Custom torsion spring manufacturing

Torsion springs manufactured to your specifications

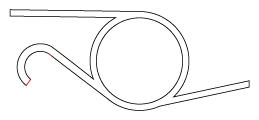

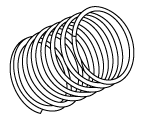

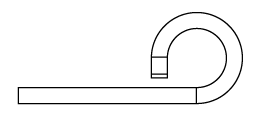

Torsion springs are used to provide resistance in a variety of angular (torque) loading conditions – the most common being hinges and other similar applications. They can store and release angular energy or statically hold a mechanism in place. As the spring winds, the coil diameter decreases and the body length increases. Double torsion springs offer higher precision and consist of two coils wound in opposite directions.

- Specialized tools from SMI to help you design your next spring project.

- Responsive design team keeps your custom spring project on track.

- Test new spring designs and improve product performance with rapid prototyping.

Specifications

Common materials

- Spring Steel

- High Carbon Steel

- Low Carbon Steel

- Nickel Plated Carbon Steel

- Stainless Alloys

- Non-Ferrous Materials

- Elgiloy®

- Hastelloy®

- Monel®

- Inconel®

- Additional options available

Material options

- .007 In. to .500 In. wire diameter

- Up to 2.0 in. bar stock

- Round wire

End options

- Bent

- Hooked

- Twisted

- Looped to suit project specs

Finishes

- Zinc

- Gold Iridite

- Passivated

- Dykem®

- Additional options available

Industries we serve

Automotive

We produce a wide range of customized spring solutions for the automotive market including torsion springs. We work with a wide range of materials and wire size.

Medical equipment and devices

Medical devices require precision torsion springs of the highest quality. Our ability to produce your custom design supports essential medical equipment.

Industrial machinery

Our ability to produce precision torsion springs of any lot size is a core strength. We produce your industrial design with a wide range of materials and wire sizes.

Aerospace

Aerospace torsion springs require precision manufacturing and are custom produced in a variety of lot sizes, materials and wire sizes.

Agriculture

Our agricultural customers rely on us for custom torsion spring solutions of any lot size, wire size, and material to support agricultural equipment and parts.

Electronic devices

Precision torsion springs are used in a wide variety of electronic devices. We will produce your custom spring in any lot size out of a wide range of materials and wire sizes.

Commitment to quality torsion springs

Our commitment to superior manufacturing with quality systems and stringent inspection will help meet the demanding standards of many industries. We have effectively implemented ISO 9001:2015 quality management systems, providing evidence to customers, suppliers, and employees, of our commitment to provide quality products and services

Springs Inc. provides quality control processes including first article, and in-process inspection, SPC tracking, PPAP’s, FMEA and quality control plans including performance testing.

Frequently asked questions

What materials do you use for spring manufacturing?

- Music Wire

- Hard Drawn / Valve Grade

- Stainless Steel

- Oil Tempered

- Hastelloy

- Elgiloy

- Monel

- Chrome Silicon / Valve Grade

- Chrome Vanadium / Valve Grade

- Phospher Bronze

- Beryllium Copper

- Spring Brass

- MP35N

- Zinc Coated Music Wire

- High Tensile HD

- Titanium

- Other Alloys? Ask!

How can I make my spring stronger?

Adjusting Various Factors, such as:

- Material Type

- Wire Diameter

- Number of Coils

- Spring Specifications (OD/ID)

- Additional Operations (Present / Set to Solid / Shot Peening / Passivation)

Can you determine the lifecycle of the spring?

While there are limitations in certain circumstances, part of our design process gives an expected lifecycle of spring, assuming we have the necessary information on the demands/stresses put on part. (loads, environmental conditions, etc.).

How are you able to test/verify parts meet specifications?

We are able to test and verify part specifications with our dedicated QA team and their familiarity and adherence to our ISO Certification, PPAP procedures, and first article inspections.

Our QA team leverages resources and techniques to test many factors with our wide variety of equipment including load testers, height gauges, and many other devices.

Do you have recommendations to improve performance?

Our team works with customers to better understand their needs and the demands on their parts to deliver creative solutions and better understand where the highest stresses are within the part and its desired function.

Do you have standard tolerance requirements?

We base our tolerancing off of SMI Tolerancing Guidelines, but in certain scenarios, we are able to do better than what is provided.

Are you able to offer rapid samples/prototyping?

Yes, average 1-2 weeks depending on needs/operations.

Do you have a requirement for minimum orders?

No, but there is a “standard” baseline cost required for us to make parts, which includes material sourcing and equipment setup time. We will manufacture any quantities desired, but the per-piece pricing improves as quantities are higher.

What is your lead time?

It depends. Please give us a call and lets see what we can do.

What options do you have for shipping/packaging?

We offer customer packaging solution such as tacky packing, sorting, bagging, and can handle your special request.

How do you determine material selection?

Material selection is based on demands of the parts, environment, loads, part cycling, etc.

How do you determine if parts are overstressed?

Our design team work with your specifications and our SMI software to determine where stress may be evident.

Additional spring and wire form products

Compression springs

Open-coiled helical springs that resist compressive force applied axially.

Extension springs

Helical springs store energy and provide resistance on pulling forces.

Wire forms

Endless number of custom designs based on material, form, and function.

Precision spring and wire form manufacturing for over 30 years

We provide ISO certified service and delivery that will exceed your expectations while providing great jobs in our community of Forest Lake, Minnesota. We are the partner you seek to provide the springs and wire forms you need when you want them.

Need assistance?

Connect with our design team

We offer a customer-centric manufacturing approach to engineering and design. Leveraging technology and modern equipment to brainstorm solutions to issues, new product development or existing part modifications.