Precision springs and wire forms

Helping customers problem-solve their custom spring and wire form needs for over 30 years.

Design assistance for your unique application

Customer-centric manufacturing approach to engineering and design

Leveraging technology and modern equipment to brainstorm solutions to issues, new product development or existing part modifications.

OUR CAPABILITIES

Manufacturing commitment to quality & precision

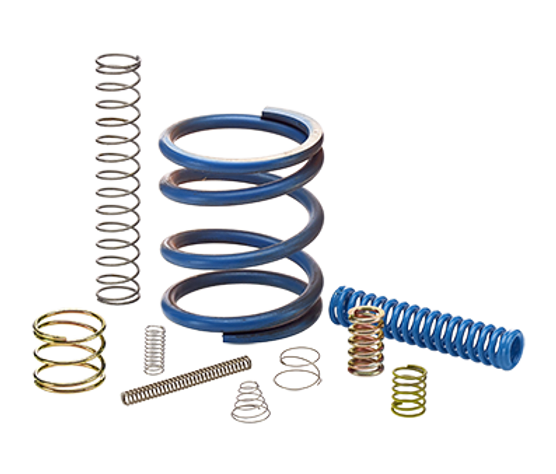

We understand every project is unique and requires multi-level assistance for a successful outcome. Our team has extensive experience working with a variety of spring types.

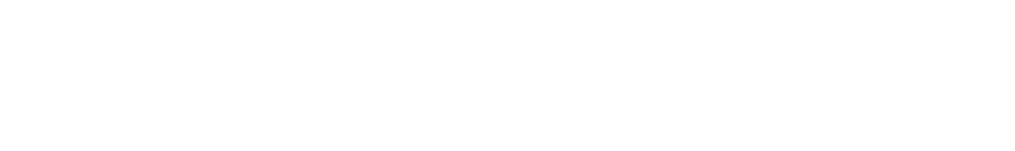

Compression springs

Open-coiled helical springs that resist compressive force applied axially.

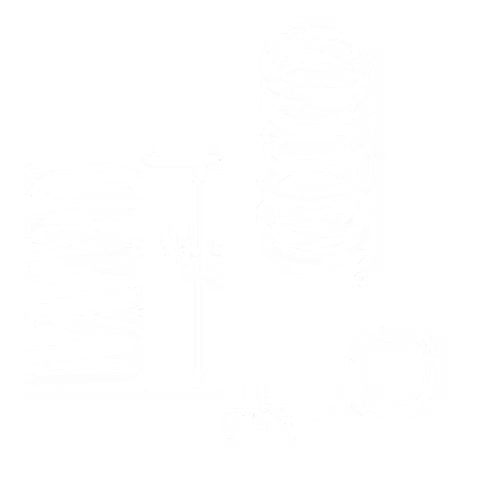

Extension springs

Helical springs store energy and provide resistance on pulling forces.

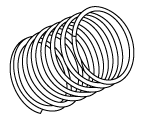

Torsion springs

Helical springs providing rotational/torque energy, come in single or double-bodied.

Wire forms

Endless number of custom designs based on material, form, and function.

Precision spring and wire form manufacturing for over 30 years

We provide ISO certified service and delivery that will exceed your expectations while providing great jobs in our community of Forest Lake, Minnesota. We are the partner you seek to provide the springs and wire forms you need when you want them.

INDUSTRIES WE SERVE

Extensive experience in a wide variety of applications

Precisely designing and testing springs to meet the quality, performance and safety needs for a variety of industries.

From fortune 500 corporations to inventors/entrepreneurs, every project has specific needs. Through our proven experience and attention to detail, we strive to get you the right part at the right time, every time.

Automotive

Industrial

Agriculture

Medical

Aerospace

Electronic

Value added services

Full-service spring manufacturer

Identifying cost-savings solutions for our customers through improved efficiencies and reduced operations.

- Passivation, shot peening

- Dykem, powder coating or plating

- Grinding, stress relieving and heat treating

- Custom packaging and inventory management

- Rapid prototyping

- Load testing, life cycle analysis and improvement

- QA – Failure modes and effects analysis (FMEA)

- Pre-production approval process (PPAP)